Industries

UV Industries

Scandico Systems strive to offer and achieve premium quality control lamps, providing fast response times, high resolution, and increased operating ranges. They are designed to be easy-to-use and versatile, making them perfect for a wide range of applications. Thousands of companies worldwide trust our UV blacklight inspection lamps to play an integral role in their processes and products for a wide variety of industries.

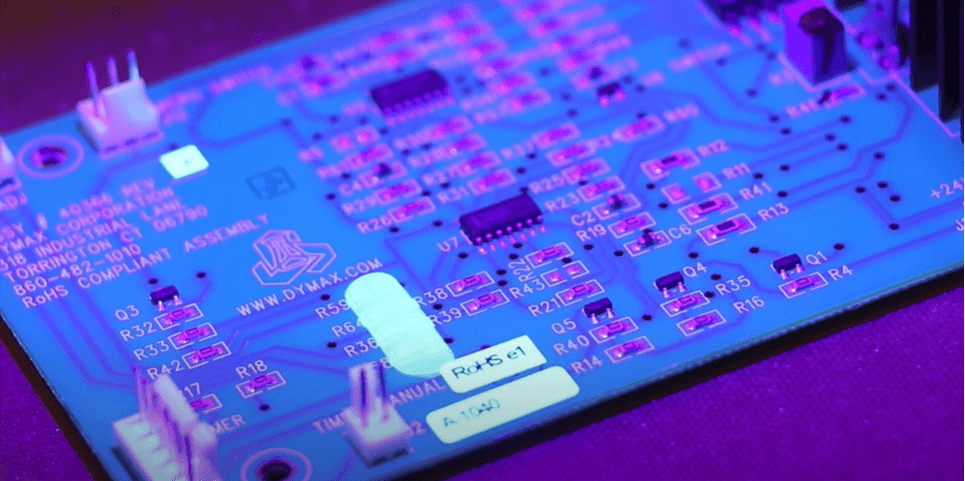

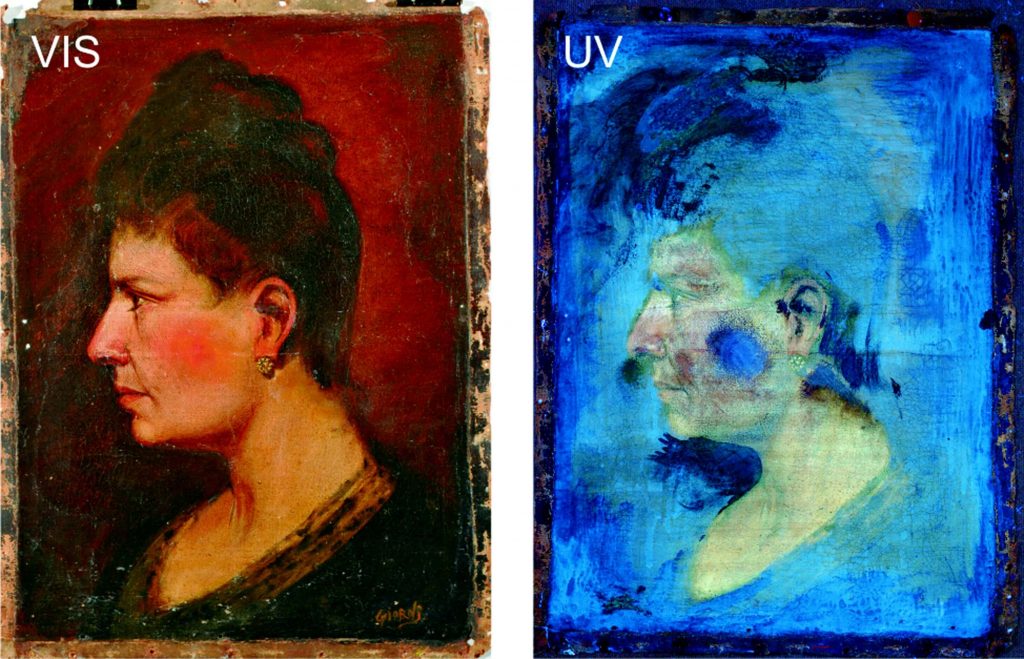

Nondestructive testing or non-destructive testing (NDT) is a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage. The terms nondestructive examination (NDE), nondestructive inspection (NDI), and nondestructive evaluation (NDE) are also commonly used to describe this technology. Because NDT does not permanently alter the article being inspected, it is a highly valuable technique that can save both money and time in product evaluation, troubleshooting, and research.

The fluorescence of gems and gemstones is a result of UV radiation absorbed by the impurities or structural flaws of the stones. Ultraviolet fluorescence is used by gemologists, jewelers and collectors to separate the artificial gemstones from the real, or in determining if the gemstone has been heat-treated. A Scandico Systems UV light can be used on a large sample of stones, saving time and money. Similarly, the fluorescence of minerals is best viewed under UV light conditions. The color variations displayed by certain minerals are a result of impurities, called activators, which absorb the ultraviolet radiation and emit visible light and heat. Different minerals emit different colors, making identification simple and easy. Scientists and hobbyists alike can perform their work in the field with Marvel C4 cordless UV lamp to view limitless minerals in their natural environment.

Scandico Systems UV inspection lights are used to reveal invisible contamination on surfaces, highlighting areas either missed or not cleaned properly. Ideal for audits, evaluating different cleaning products and training staff. Our professional UV inspection lamps are used in hospitals, care homes, theaters, dentists, doctors surgeries, offices, call centers, hotels, changing areas, etc..

Scandico Systems, 2021 All rights reserved

Scandico Systems, 2021 All rights reserved